DESMI Ocean Guard develops and sells ballast water treatment systems for the removal of living organisms from ships’ ballast water. The company has developed type approved ballast water treatment systems and is located in Nørresundby, Denmark.

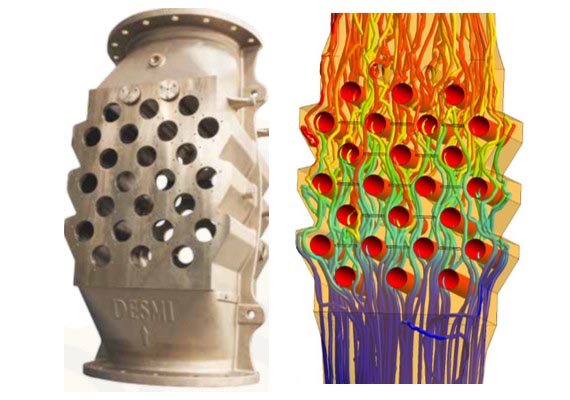

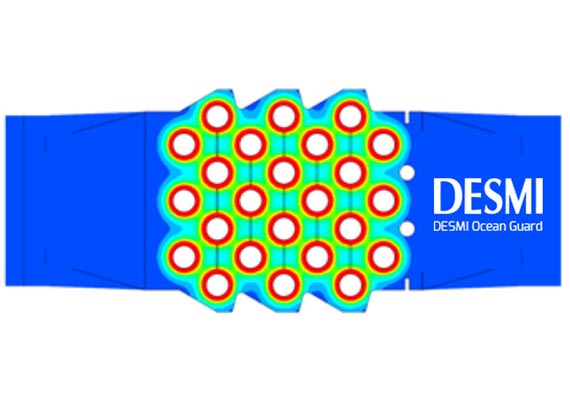

In collaboration with the Engineers at Desmi Oceanguard, R&R Consult designed six standard sizes. Each unit was optimized with respect to a small footprint and very high treatment efficiency.

The UV unit has a unique shape and patent pending, which is a result of numerous numerical investigations. We have assisted in the design of the UV unit by doing the CFD modelling of each unit. The work has been both challenging and rewarding and required a good understanding of fluid mechanics in order to evaluate the complex flow. Desmi Ocean Guard not only strived for a design that fulfils minimum requirements, but really aimed to develop the best-in-class solution.

High Efficiency Keeps your OPEX Down

According to DESMI Ocean Guard, the patent-pending UV unit design has very high treatment efficiency and reduces power consumption.

R&R Consult developed and optimized the special shapes of the CompactClean UV chambers based on hundreds of state-of-the-art CFD simulations. This ensures that each kW of generated UV light is utilized to the max. As a result, power consumption is as low as possible and operational costs are reduced.

UV Radiation distribution

UV Radiation distribution

All CFD simulations featured detailed geometries of the UV unit, 3D Turbulent flow, high resolution pure hexahedral mesh for capturing the large gradients of the UV radiation, DO radiation and particle tracking with UDF file for calculating received dose for each organisms. The CFD calculation approach, followed the best practice guides for calculations of UV units, with a few extensions/improvements by R&R Consult for increased accuracy and the method was reviewed and approved by Lloyd’s register.

Further info Desmi Ocean Guard

Particle flow, coloured by received dose

Particle flow, coloured by received dose