R&R Consult participated in the 7th framework program of the European commission in the Empyro project: Polygeneration through pyrolysis: Simul-taneous production of oil, process steam, electricity and organic acids – started in December 2009. The main purpose of the project was to build and demonstrate a 25 MWth polygeneration pyrolysis plant to produce electricity, process steam and fuel oil from woody biomass. The production of pyrolysis oil offers several advantages; the oil is easy to store, pyrolysis oil is second-generation biomass technology and does not interfere with the food chain and the oil is a greenhouse gas neutral biofuel.

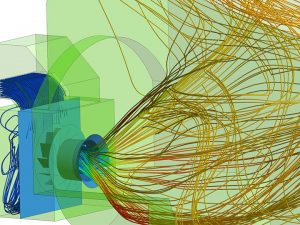

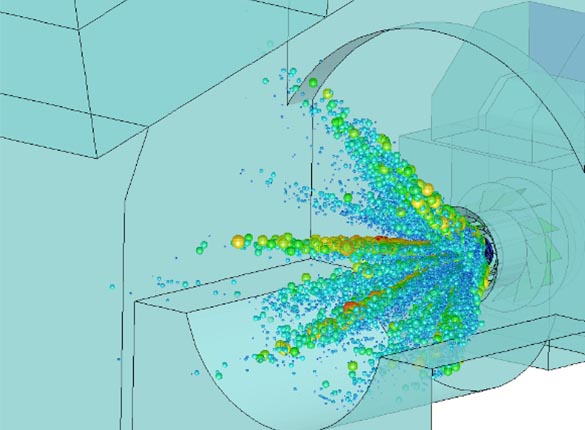

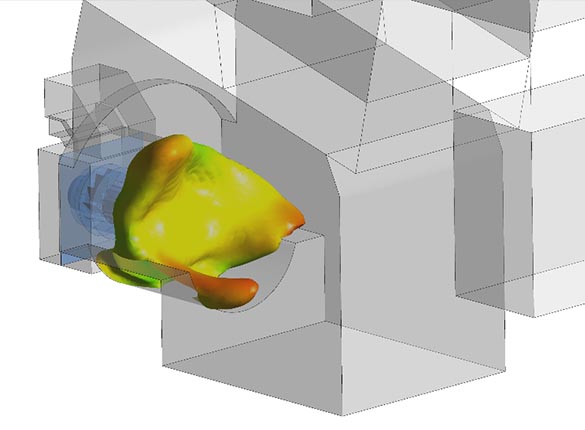

The chemical and physical properties of pyrolysis oil differ considerably from conventional fossil fuels, in regards to the physical combustion behaviour and the modelling approach. The high water content, high viscosity and high coking tendency are particularly challenging and can cause incomplete combustion and fouling. Development of a new burner is costly and CFD modelling of the combustion of the pyrolysis oil is a valuable tool in the design process. However, a reliable model and experience is an absolute necessity. R&R Consult was chosen as partner for this project due to our many years of experience and expertise in combustion modelling and oil spray atomization.

We tested and evaluated whether existing combustion and turbulence models were able to capture the combustion process of the pyrolysis oil. We conducted a thorough validation program, based on available benchmarks.

The investigation revealed that standard models were not appropriate for the calculation and adjusted models were developed. For the spray modelling, no models were available and we adapted a previously developed model by R&R Consult for heavy fuel oil in twin fluid atomizers.

CFD calculations were then compared, with experimental data from a physical boiler test from Stork Thermeq BV, equipped with their double register dual fuel oil/gas burner.

Overall, there was a good agreement between measured species- and emission levels and the CFD result, as well as flame shape and behaviour. Thanks to the new model, better boiler and burner design can be developed for these difficult applications.

Following this approach, BTG Bioliquids BV built and demonstrated the first polygeneration pyrolysis plant in Europe, including successful, stable and low-emission combustion of the produced pyrolysis oil in a boiler made by Stork Thermeq in Hengelo, the Netherlands.

Further information at cordis.europa.eu