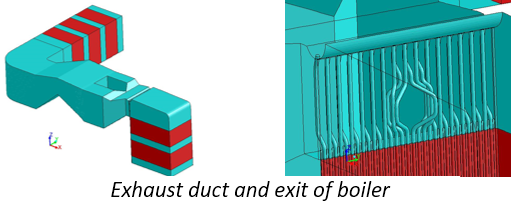

The Rodeløkka domestic heating central is located in an old historical building from 1920. A former chocolate factory and the transformation to a modern heating central began in 2010. The heat is delivered from a 100MW oil and bio- oil fired boiler. The many restrictions associated with old buildings make it a challenge to retrofit an existing building to a modern heating central. Aalborg CSP delivered the complete boiler, economiser, ducting and the installation.

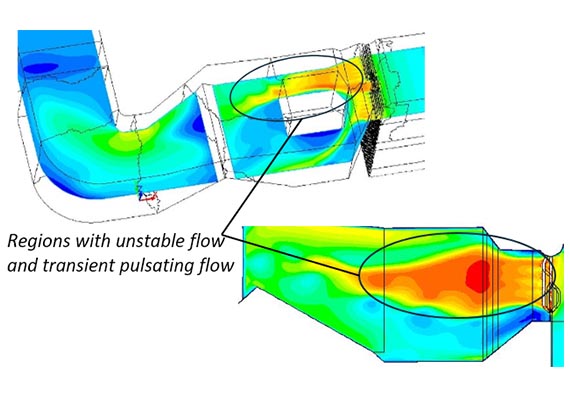

Low frequency noise and heavy vibrations had been observed from the exhaust duct from the boiler. Building restrictions made it difficult to make an optimal design of the exit duct from the boiler. The CFD investigation revealed the cause of the pulsating flow: several areas with jet like flow and reversed flow zones with eddies. Solving the problem would require a new design that would eliminate the pulsating flow without an excessive pressure drop. R&R Consult suggested and investigated a range of designs, featuring different locations and design of guiding plates. A model of our suggested solution showed that the majority of the pulsating flow would be eliminated. This turned out to be true in the real installation. As a result, the company avoided a very time-consuming and costly trial-and-error process at the plant.

Below, shows the outline of the exhaust duct from the boiler and velocity distribution indicating regions with unstable pulsating flow.

The modelling included a 3D transient turbulent investigation, with a detailed structure and with a very fine hexahedral mesh for capturing the low frequency transient pulsations.