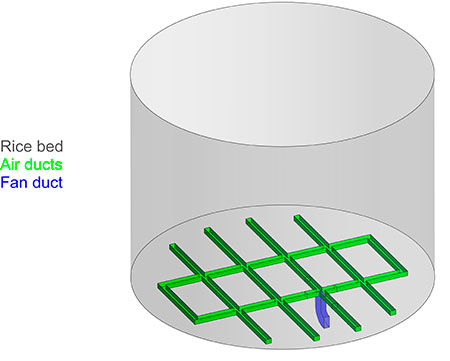

Implementing CFD in the design phase is beneficial in many applications. R&R Consult supported Skiold A/S in simulating the flow distribution and pressure loss in a rice storage silo. Reducing the pressure loss in a fan driven flow system directly increases the volumetric flow rate of air, which is important for the cooling and dehumidification of the rice bed. The system consisted of a centrifugal fan supplying air to a network of air ducts connected to the rice storage silo through a fine grate.

Rice storage silo with air ducts and fan duct

Using the fan curve and system geometry, the pressure loss was calculated with the CFD model accounting for both the air ducts and porosity of the rice bed.

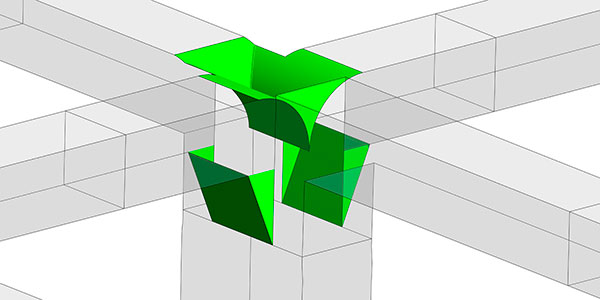

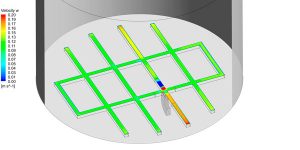

As presumed by Skiold A/S, the pressure loss in the system was high, as the flow distribution was uneven. By evaluating the distribution of supplied air in the system areas causing increased pressure drop were identified and design changes were simulated and proposed to Skiold A/S. The proposed design changes involved a flow guiding plate as well as duct expansions at two of the ducts connecting to the fan inlet.

Geometrical changes to reduce pressure loss

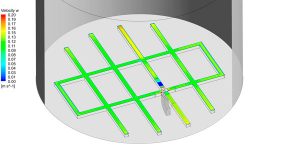

The design changes resulted in a more evenly distributed flow field as well as 6% reduction in pressure loss. As a result of the reduced pressure loss, the volumetric flow rate is increased by 9%, meaning more air for cooling and dehumidification.

Pre design change Post design cange

There exist several thousands of these installations around the world and there is a great potential for reducing the pressure drop and by that reducing the power consumption for the fan. The animation shows stream lines coloured by residence time.