Computational Fluid Dynamics (CFD) is a powerful tool for optimizing liquid systems – from improving efficiency and enhancing safety to addressing design challenges.

CFD uses advanced mathematical models and numerical techniques, rather than physical models, to explore fluid dynamics in applications such as

- ballast water disinfection

- wastewater treatment

- aquaculture and RAS (recirculating aquaculture systems)

- liquid- and air-cooled electronics thermal management

- food and beverage production processes

- hydraulic systems

- cooling systems

CFD accelerates design processes and helps develop more efficient, sustainable, and dependable liquid-centric systems. That eliminates the need for expensive, time-consuming physical models.

CFD Simulation for Optimizing Ballast Water Disinfection Systems

That’s exactly what R&R Consult did for our client, Ankron Water Services GmbH. We used CFD simulation to optimize a ballast water disinfection system and improve environmental performance.

Ankron Water Services specializes in developing and implementing innovative technical solutions for water filtration and disinfection, including ship ballast water treatment systems. One of Akron’s customers had developed a well-functioning base unit, which had been tested and approved by classification authorities. Now they wanted to scale up the unit to accommodate varying capacity needs.

To obtain approval from the classification society for the scaled-up units, additional validation was required.

This posed a challenge: Like most companies, the manufacturer had designed, developed, and tested the smallest unit in the series to save time and costs. It would be costly and time-consuming to create larger testing systems — especially since the capacity of the largest system would be 20 times larger than the base unit.

So Ankron Water Services asked R&R Consult to perform a CFD simulation on the scaled-up system to ensure and document that the larger units would match or exceed the performance of the approved base model.

Significance of Ship Ballast Water Treatment

The effectiveness of ballast water treatment is crucial for several environmental, ecological, economic and health reasons.

When ships take on ballast water in one location and discharge it in another, various organisms, such as bacteria, algae and marine species are unintentionally transported along with the water. Uncontrolled ballast water discharge can introduce invasive species that can disrupt ecosystems and harm biodiversity, which can lead to significant economic consequences. Pathogens, bacteria, and viruses in ballast water may also pose risks to human health.

To avoid these potential harmful consequences, ballast water treatment systems are designed to remove or neutralize harmful organisms before discharge.

System Functionality

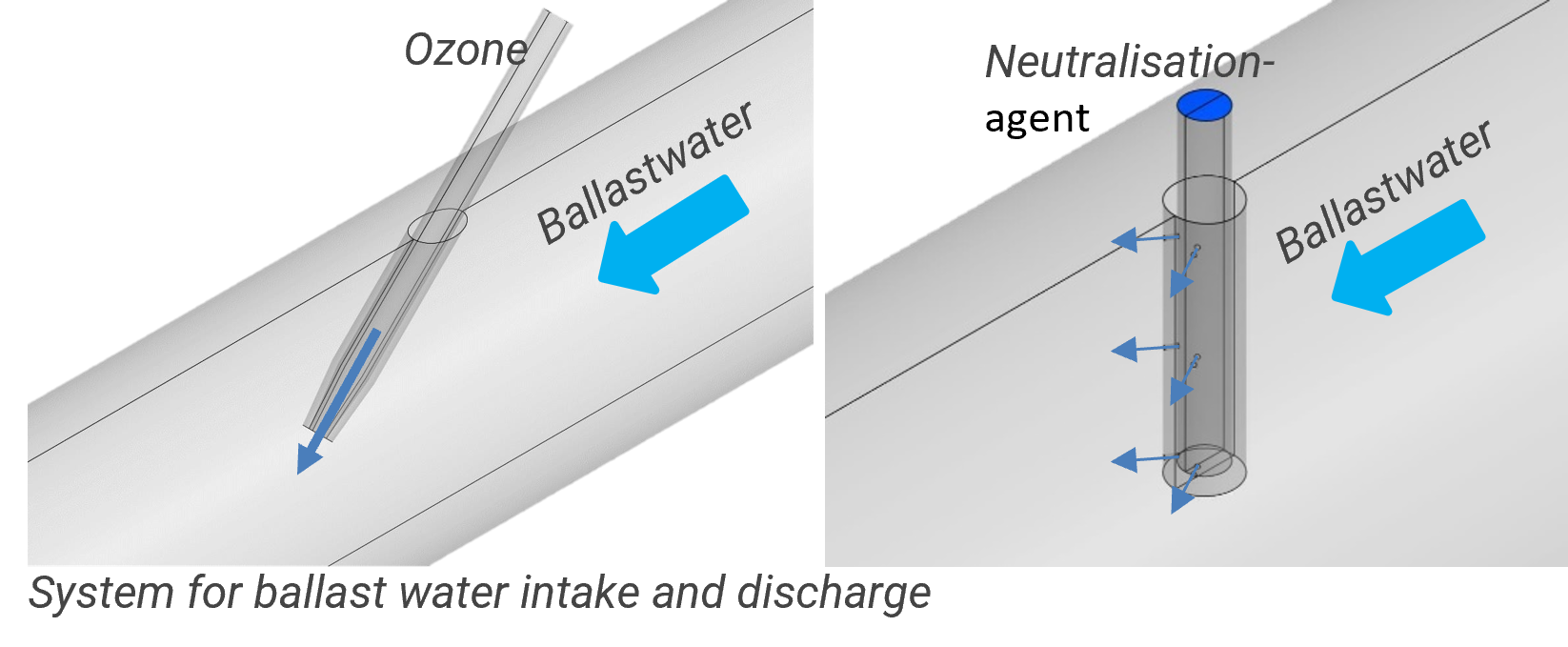

When a ship takes on ballast water from the harbor, the water is pumped into ballast tanks. In this particular model, ozone is injected into the main ballast line to disinfect the water. During the de-ballast process after the journey, the treated water is neutralized to prevent harm to the ecosystem from chemicals in the water.

To assess the efficiency of the ozone and neutralizing agent injection system in the main ballast line, the classification society had requested a scaling analysis of the base model.

How R&R Consult used CFD Simulation to Optimize Ballast Water Treatment

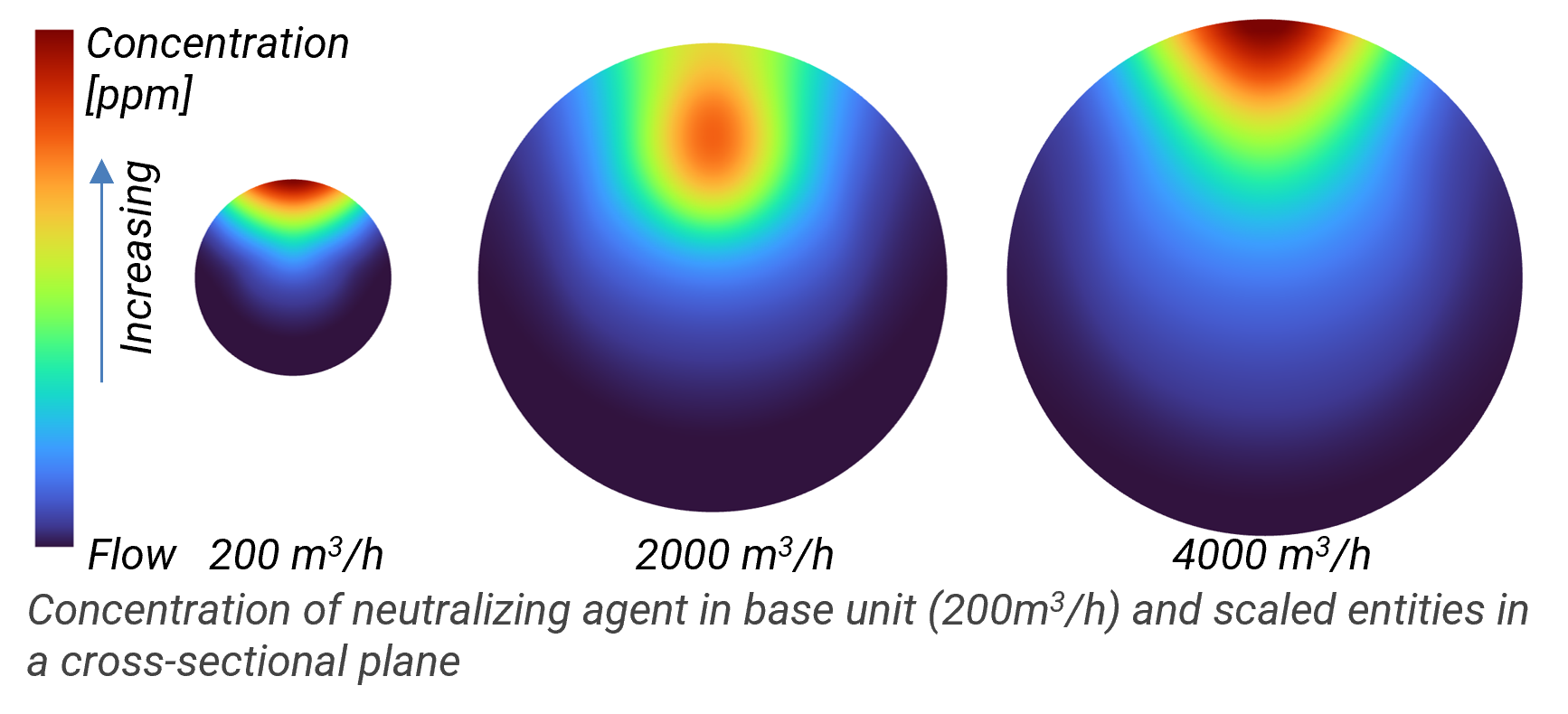

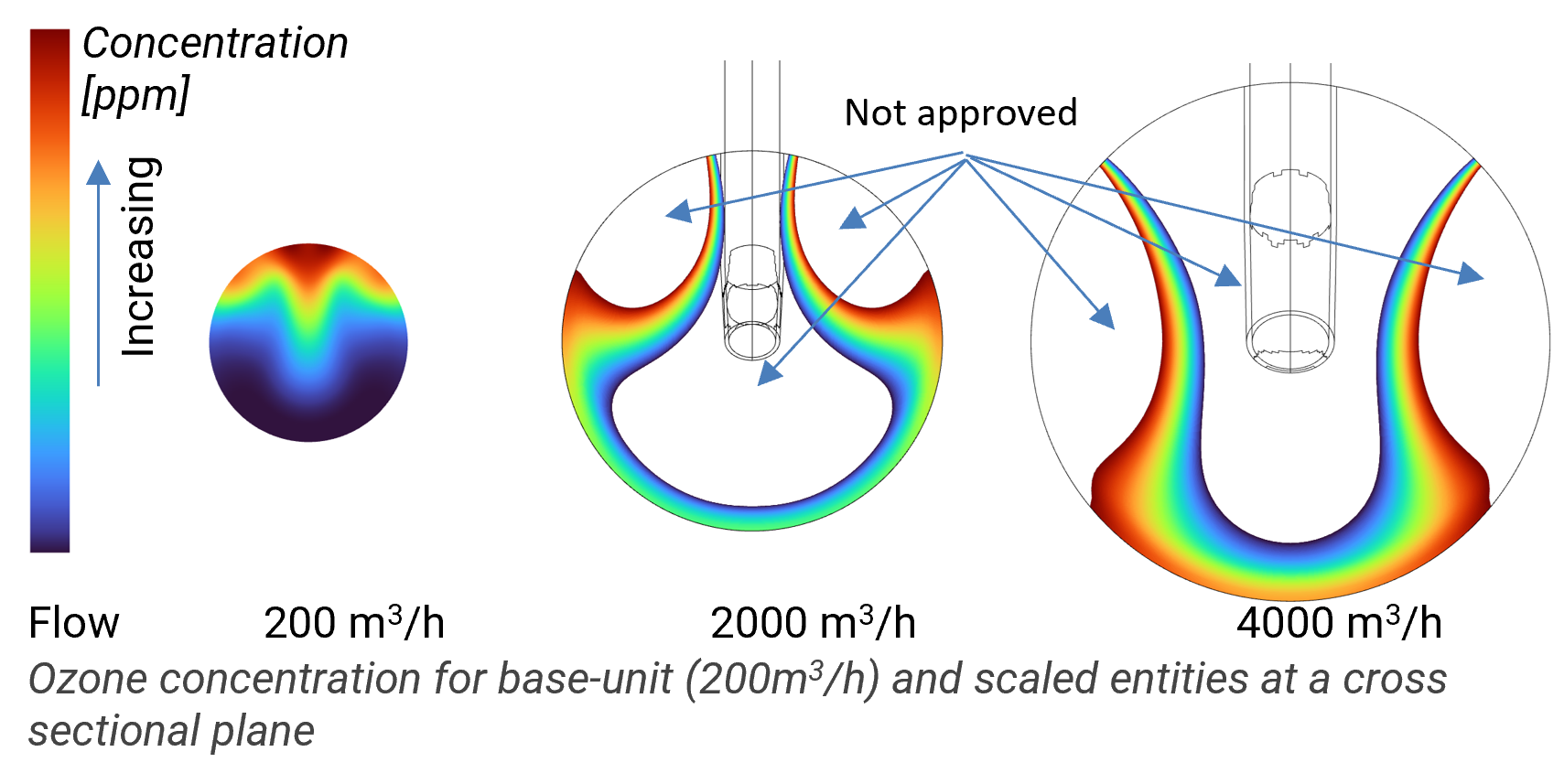

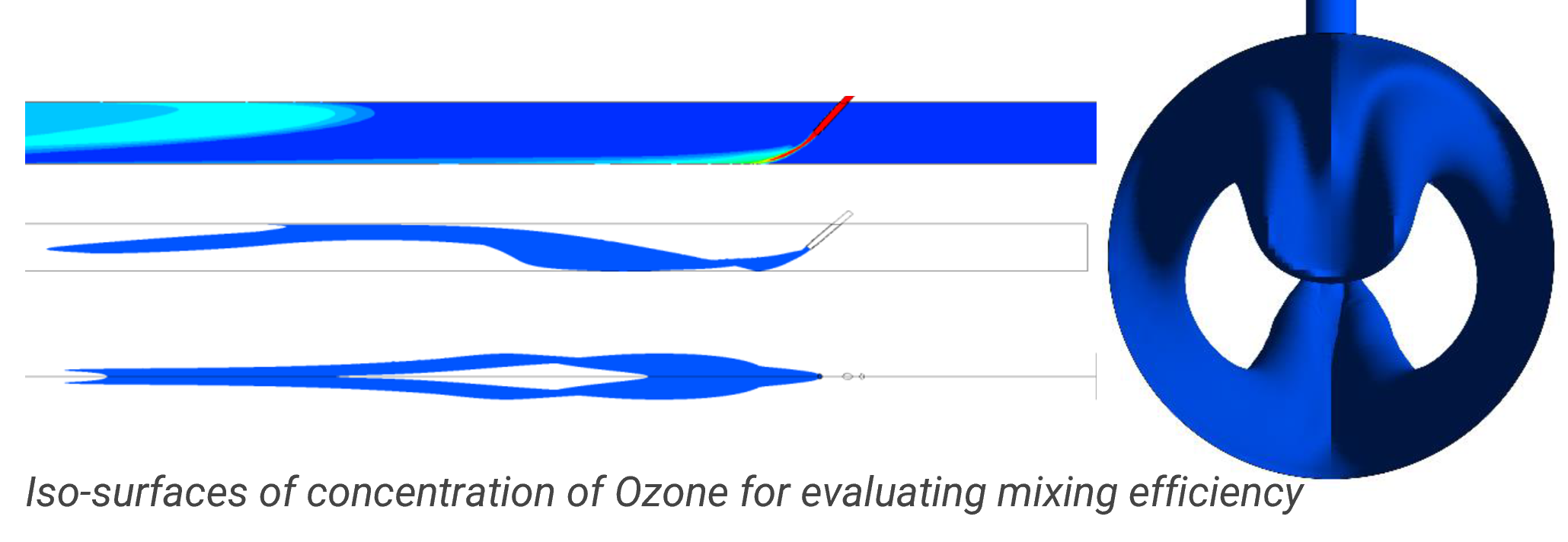

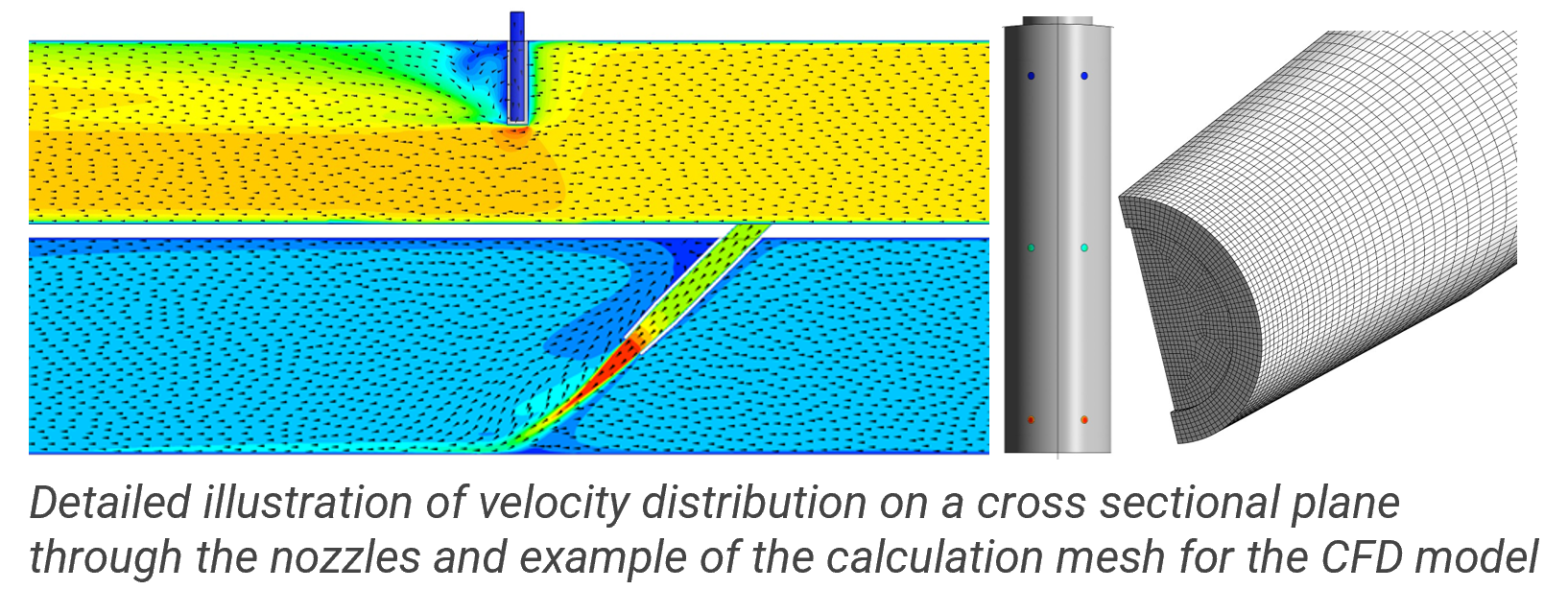

R&R Consult CFD simulated the scaled-up systems. We evaluated the mixing based on several parameters, including where the concentration was minimal and maximal, as well as the dispersion of the concentration.

The scaled units for ballast water discharge had at least, just as good or a better mixing as the base unit.

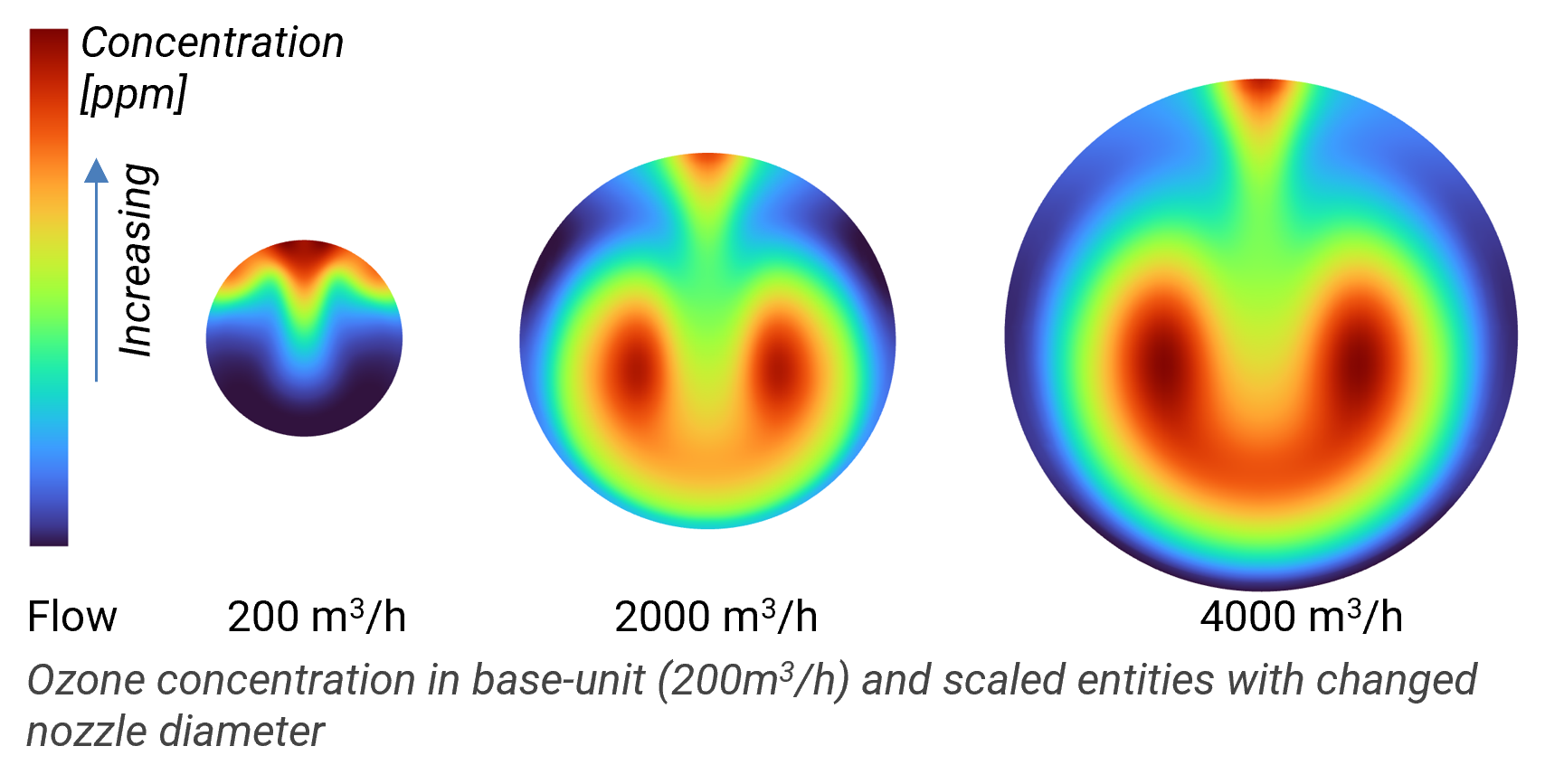

This was different for the scaled unit for water intake. The result revealed that in large areas of the ballast water intake, concentrations were above or below those of the base unit (see figure with Ozone concentration). Thus, the scaled units didn’t fulfil the mixing requirements and couldn’t be approved.

The analysis also allowed us to identify the cause of suboptimal mixing, an unfavourable ratio between the ballast water speed and the ozone mixture. As a solution, we proposed changes to the diameter of the nozzle for ozone injection to enhance the mixing.

Based on our CFD analysis and recommendations, some simple design changes were made to the ozone intake. This resulted in significantly improved and faster mixing (see figure with Ozon concentration with changed diameter). As a result, the redesigned scaled systems matched or exceeded the performance of the approved base model.

Approval and Certification

The last step to certification of the scaled units was to seek approval from DNV GL. It’s a global quality assurance company that certifies that e.g. offshore and maritime structures meet safety, environmental and performance standards.

To ensure the accuracy of our results, DNV GL required very thorough and extensive documentation of all aspects of our calculation model.

R&R Consult has extensive experience with documentation for classification societies from a wide range of projects, including Desmi Ocean Guard Compact Clean and Ozone leakage from pipe fracture in engine room. Drawing on this experience, R&R Consult had a fruitful collaboration with DNV GL and obtained approval.

Ankron Water Services customer received authorized certification for use in marketing and further development of their product series.

Advantages of CFD Simulation in Design, Validation and Performance

This case highlights how CFD simulation effectively addressed the challenge of scaling up an already approved system:

- CFD is a great verification tool because it enables numerical validation of systems and process units. This eliminates the need for cumbersome and expensive physical tests. This is particularly beneficial when scaling units to larger capacities.

- CFD simulations provide detailed visual representations of the system, which gives an in-depth understanding of the product. This is essential for optimizing and evaluating scaled units.

By adding extra detail, R&R Consult ensured an efficient validation process. With our experience and expertise, we not only contributed to the client’s success. We also improved environmental sustainability.

Are you interested in learning more about how we can help you design or optimize your product?