CFD Simulations for Switchgear Safety Evaluation and Emergency Systems Testing

Computational Fluid Dynamics (CFD) simulations are an invaluable help when evaluating emergencies, such as arc faults in switchgears.

A CFD analysis can document hazardous gas dispersion and predict pressure and temperature distribution. With this critical evaluation, you can optimize emergency safety measures, enhance system performance and improve personal safety, environmental safety and structural integrity.

At R&R Consult, we modeled a switchgear pressure-release system during a potential arc fault in collaboration with a leading wind turbine supplier.

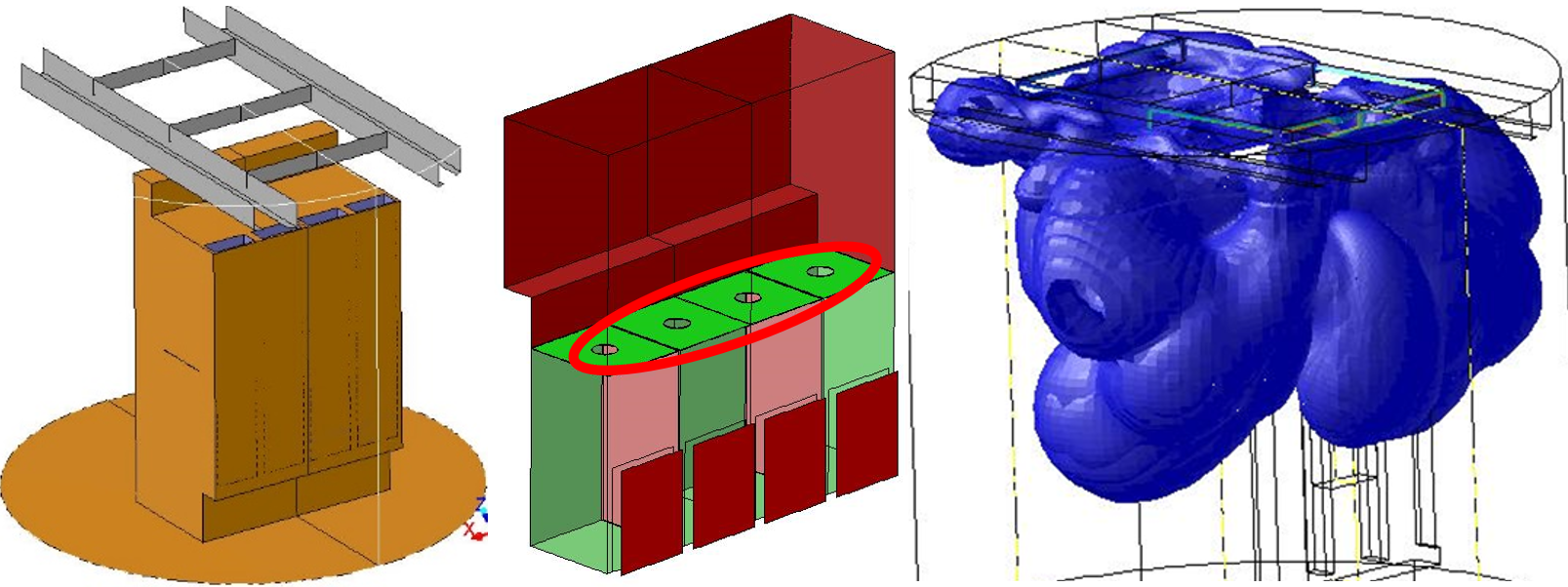

Outline of switchgear PressureValves Iso-Contour with 1000ppm SF6

A Shiftgear Emergency — a Safety Challenge

SF6 gas is used as an insulator within the switchgear. SF6 gas is normally highly stabile, but can become very reactive under extreme temperatures, high electrical stress or exposure to an electrical arc.

In the event of an arc fault, extreme temperatures, reaching up to 20,000 degrees Celcius, trigger a surge in gas pressure and dispersion within the switchgear room. This rapid escalation of pressure and temperature within the confined SF6 gas can generate shockwaves at high velocities (sonic speed). If uncontrolled, this could lead to an explosion, potentially endangering nearby individuals and causing substantial material damage.

To prevent hazardous situations, an emergency pressure valve is installed. It opens at a pressure of 180 kPa, safely releasing the gas from the cabinet into the surroundings.

Concentration of SF6 gas at the bottom of the cabinet after pressure relief

How R&R Consult used CFD Simulations to Help Improve Emergency Safety Systems

The customer wanted to conduct a safety evaluation of a pressure relief system during an arc fault in a wind turbine switchgear. The purpose was to enhance human and environmental safety and optimize the design of the switchgear.

However, modeling such an emergency — where the enclosed SF6 gas rapidly increases in pressure and temperature and may generate shockwaves at high velocities (sonic speed) — posed a challenge. These computations required significant expertise and experience in thermo- and fluid dynamics. So we were requested at R&R Consult to conduct the CFD analysis.

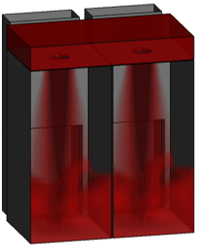

Temperaturecontours at different timesteps

Temperaturecontours at different timesteps

The Result of the CFD Analysis

The result was a vivid model of the unstable situation during a potential arc fault, which detailed how pressure increased and gas dispersed in the switchgear room.

Our CFD analysis clearly showed the unstable conditions during a potential short circuit in the switchgear. The model accurately predicted the dispersion and concentration of hazardous gases and how the pressure and temperature increased within the switchgear room.

This was crucial for evaluating personal safety and optimizing safety measures.

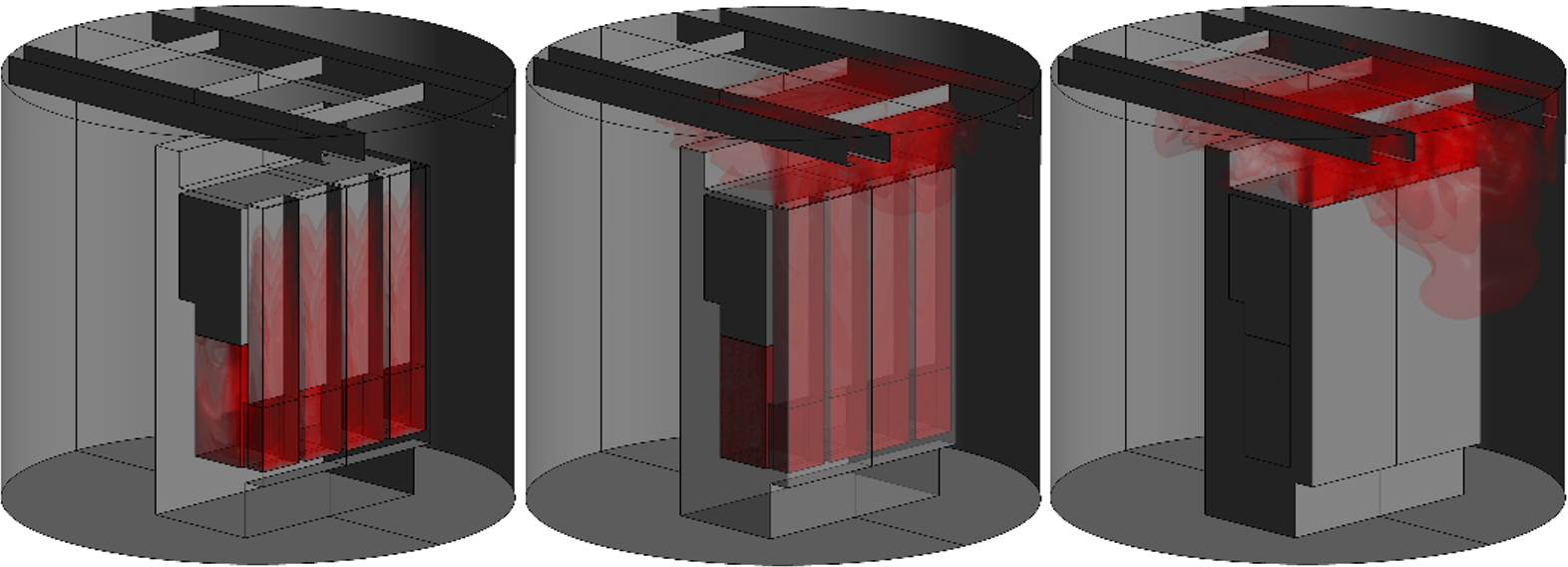

Visualisation of the dispersion of the SF6 gas as function of time, by iso-surfaces of 1000ppm concentration.

Visualisation of the dispersion of the SF6 gas as function of time, by iso-surfaces of 1000ppm concentration.

Another of our examples of the use of CFD simulation for safety can be found here, Evaluation of Ozone Leakage.

How CFD Simulations can Enhance Safety

A CFD simulation has several advantages and practical applications when it comes to switchgear safety evaluation:

- Ensuring personal safety: A CFD model depicting gas concentrations and temperatures in the surroundings can help assess and improve the personal safety of people working near switchgears.

- Testing emergency safety measures: By simulating arc faults, we can assess the effectiveness of emergency safety measures, such as pressure relief systems. The ability to predict gas distribution is a significant advantage when develoing and enhancing safety protocols.

- Design optimization: When optimizing mechanical designs in switchgear systems, it’s essential to know pressure and temperature distributions during arc faults. This can enhance their robustness and safety. Pressure and force data from the model can also be used to ensure a robust structural design.

- Protecting critical components: Our model revealed gas concentrations and temperatures in the surroundings. With this data, critical components can be strategically placed away from potential short circuits or explosions.

- Compliance documentation: The detailed safety documentation generated by the CFD simulation can demonstrate compliance with regulatory requirements and safety standards in case of an emergency.

As the this case exemplifies, a well-crafted CFD analysis offers invaluable insights into system performance and personal safety. All without the need to build expensive and time-consuming physical models.

If you’re ready to make more informed decisions and create a safer environment, contact the experts at R&R Consult today. With more than 25 years’ experience within CFD, you can count on us to tailor solutions to address your unique challenges.

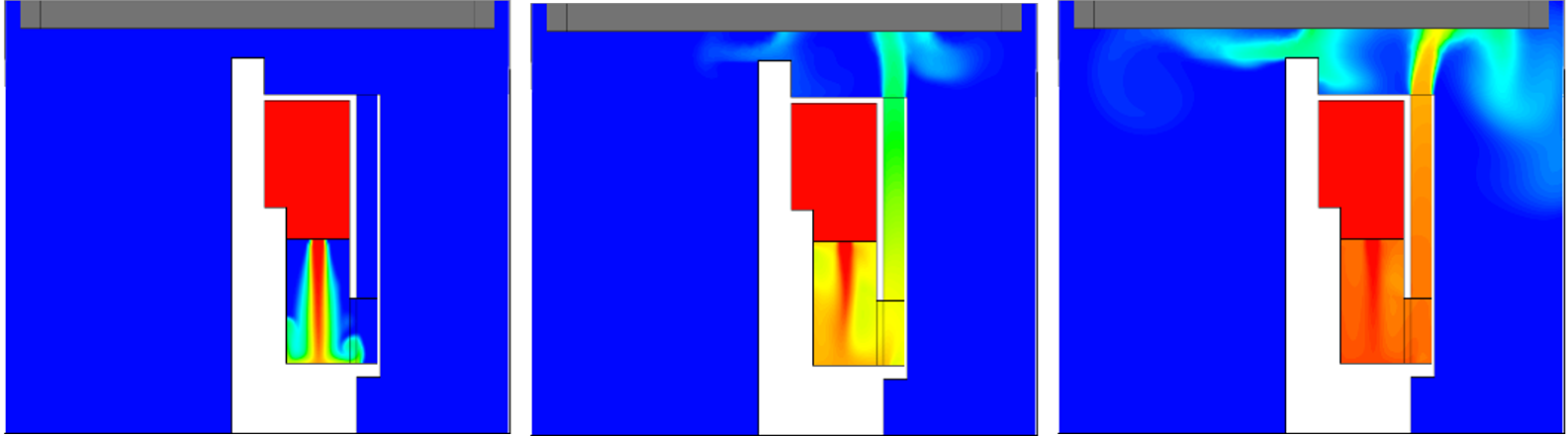

Below animation from the CFD analysis shows how the SF6 gas is expelled from the bottom of the cabinet through the pressure relief valve and is rapidly dispersed to the duct that safely release the gas out in the top of the compartment and surroundings.

Transient CFD visualisation of concentration of SF6 gas.