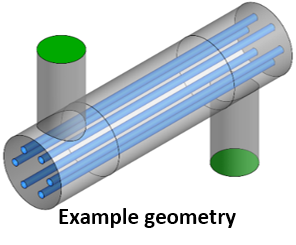

Computational Fluid Dynamics (CFD) is an efficient and valuable tool for evaluation and optimization of UV decontamination units. UV reactors are used in a variety of fields, such as decontamination of drinking water, industrial processes, ballast water and wastewater treatment. CFD can help map the fluid flow and UV radiation field of complex geometries, and provide detailed insight into the path and dose of microbial organisms.

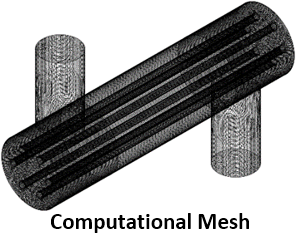

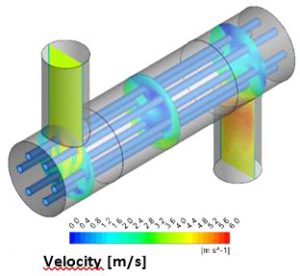

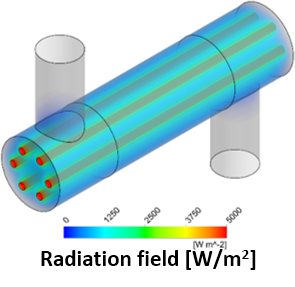

The simulation initially solves the flow field, and accounts for turbulent dispersion. Post-processing of the flow field provides valuable information about pressure losses, and highlights ill-defined flow patterns, such as flow separation and recirculation zones. The model also simulates the UV radiation field and can be adjusted to accurately capture the influence of wall emissivity, diffuse reflection, and Ultraviolet Transmittance (UVT).

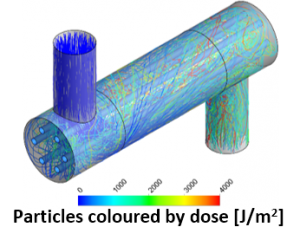

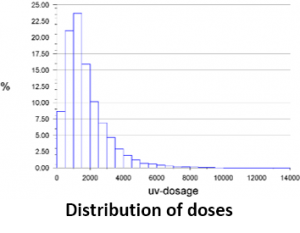

The microbial are simulated as discrete solid particles, and the absorbed dose is calculated as a function of retention time in the radiation field and the local radiation intensity. Applying a sufficiently high number of particles supplies the user with a statistical analysis regarding mean-, maximum-, minimum-, and standard deviation of dose. With the use of a log-inactivation curve of the relevant microbial, the results can also account for RED (Reduction Equivalent Dose). This may then readily be used for evaluating unit performance and comparisons.

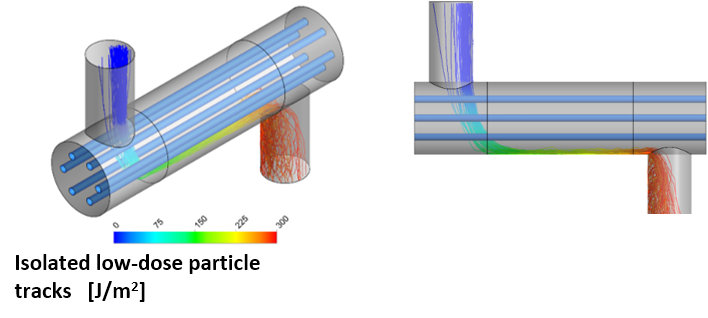

Through post-processing it is possible to isolated single particles, which may be used to pinpoint the root cause of potential dose variation, supplying additional highly valuable data regarding the operation of the UV-reactor.