R&R Consult and ECA Engineering redesigned the piping system for a marine scrubber. The objective of the design change was to reduce the back pressure on the exhaust system, as this directly impacts the power consumption of the engine. Space is usually limited in marine applications, which imposes design restrictions that also must be considered. The piping system connects the exhausts from the main and secondary engines and directs them to the scrubber.

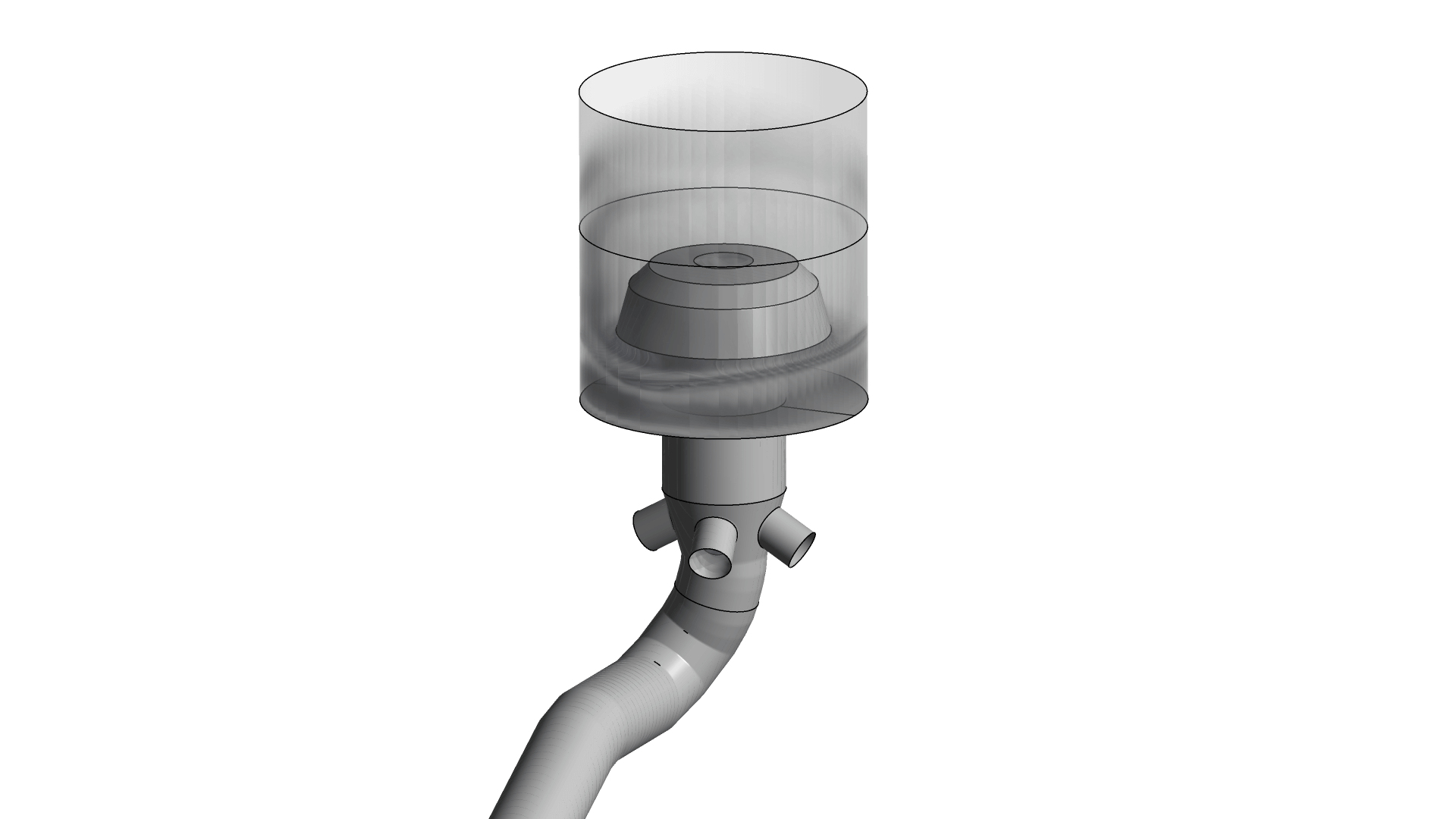

Scrubber and manifold domain (new design)

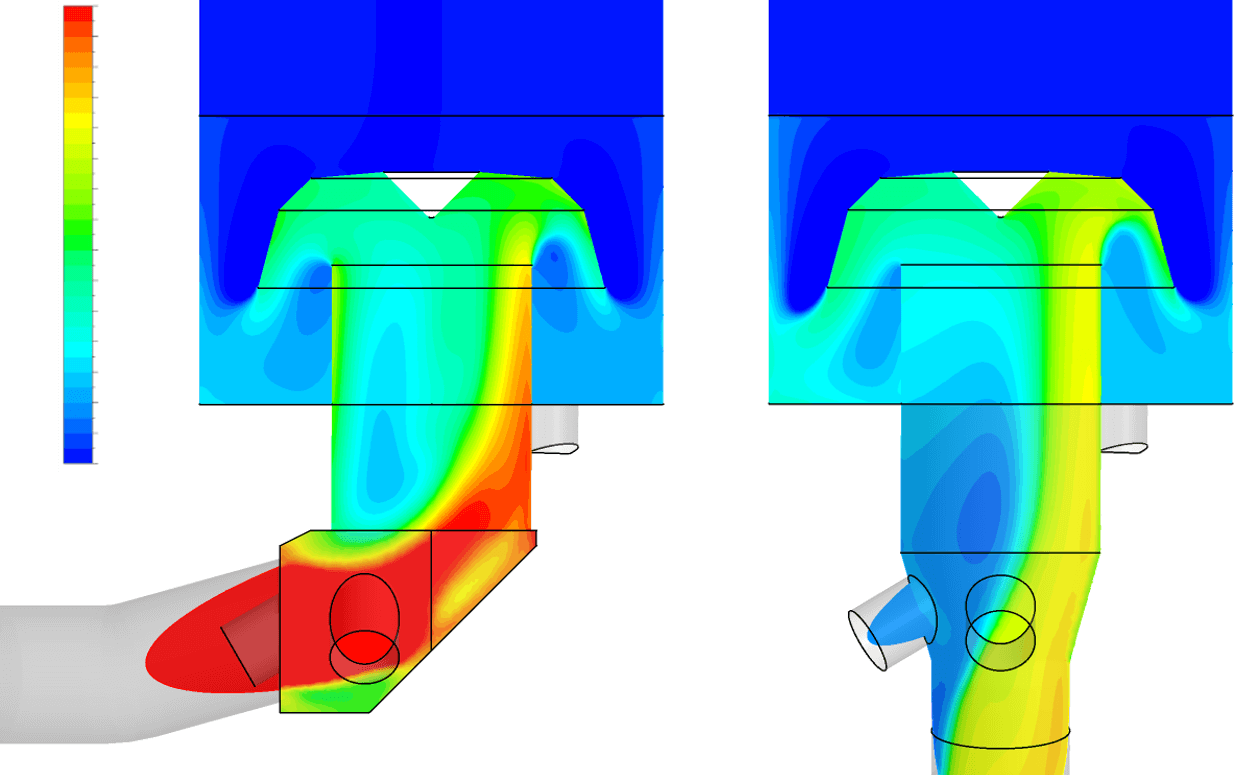

CFD is a powerful tool in both analyzing system performance and quickly evaluating various design changes. The CFD analysis of the initial design showed that the highest pressure loss occurred across the manifold connecting the piping to the scrubber.

Initial and new design Pressure distribution

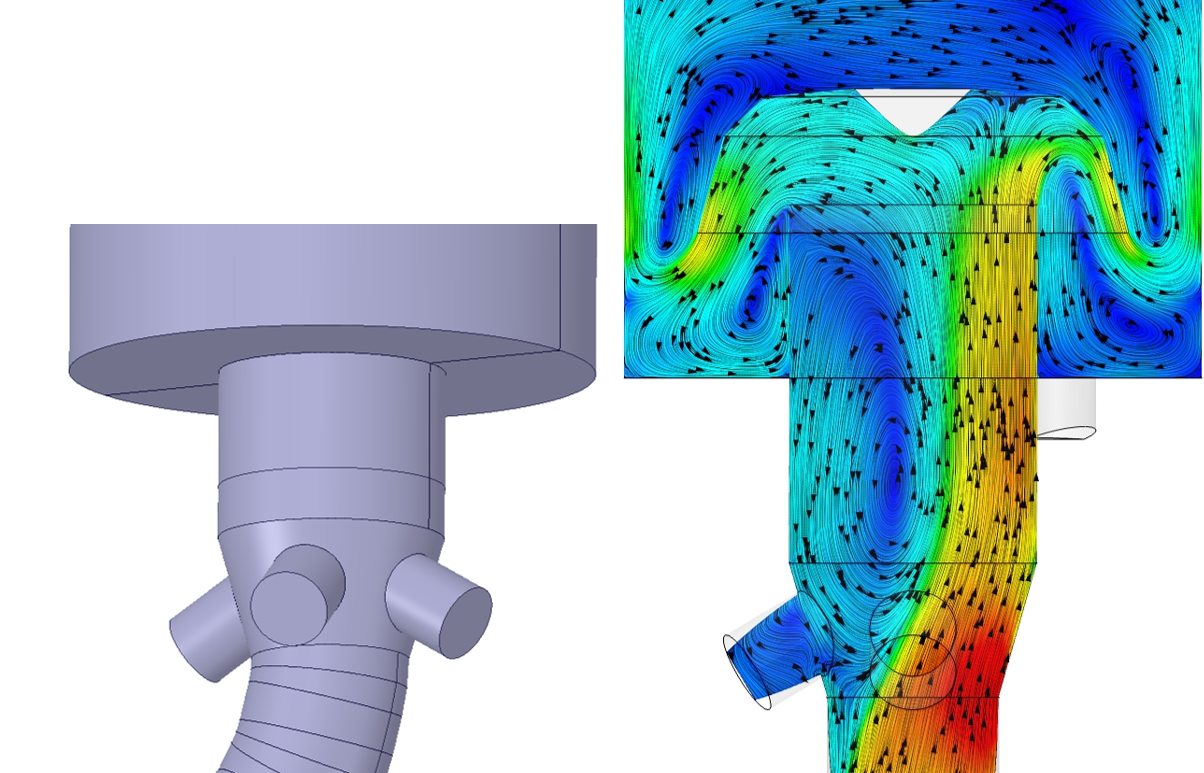

We redesigned the manifold to decrease pressure loss and ensure a uniform axial velocity field in the scrubber. The new design decreased manifold pressure loss by 50 percent and total pressure loss by 28 percent. Depending on load and operation this can amount up to a saving in power of 30 to 40 kW.

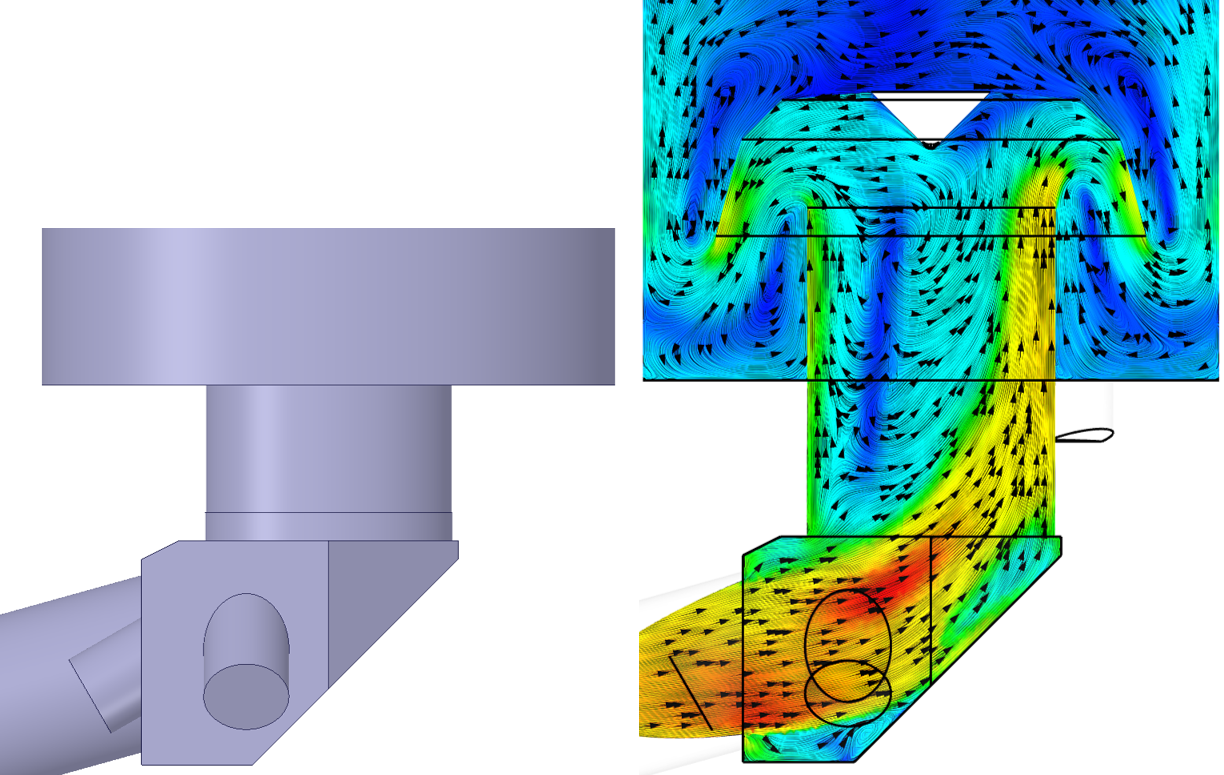

Initial design

New design

Initial and new design velocity fields